Latest IDC research on the critical role of track and trace in supply chain visibility.

DOWNLOAD NOW

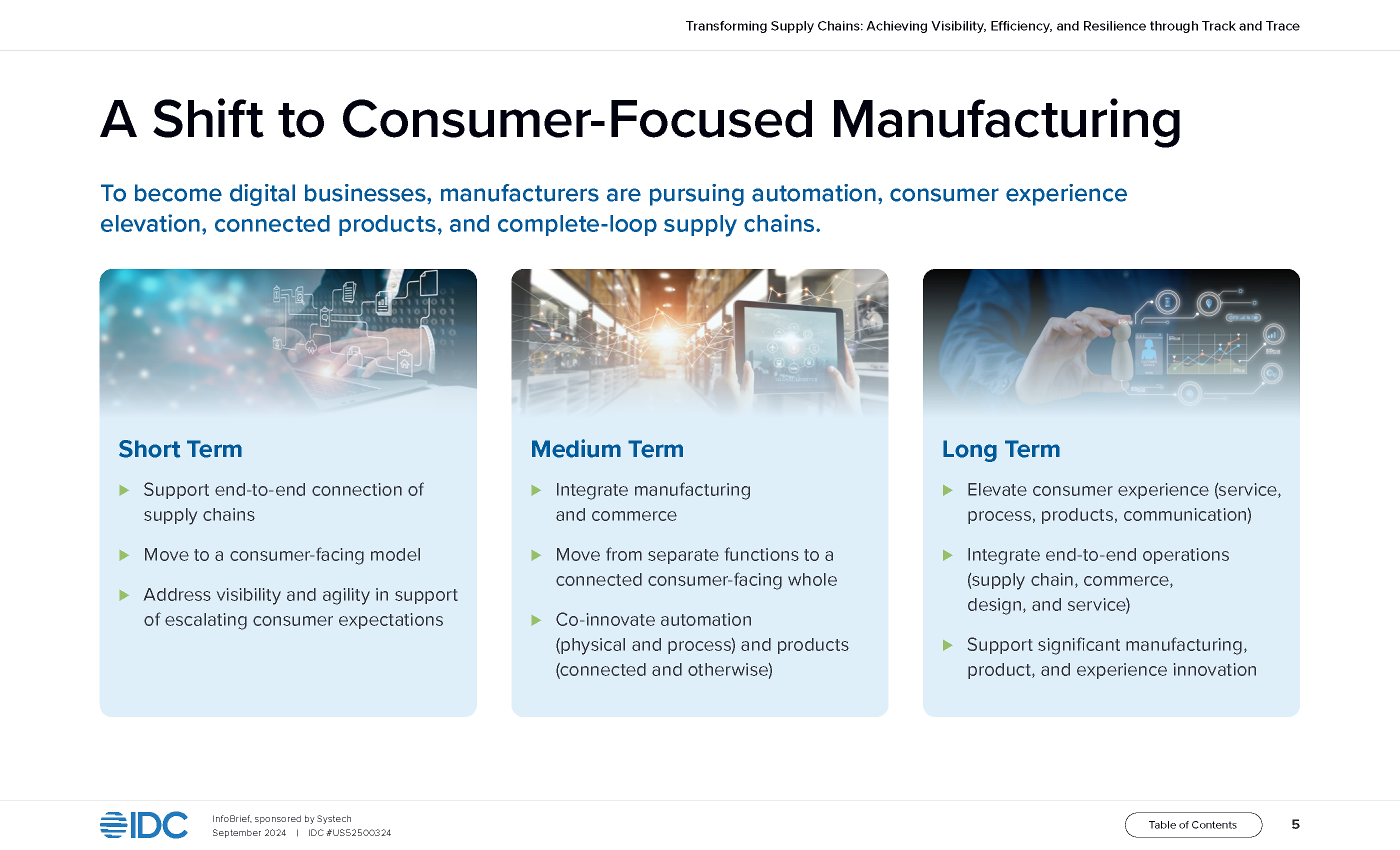

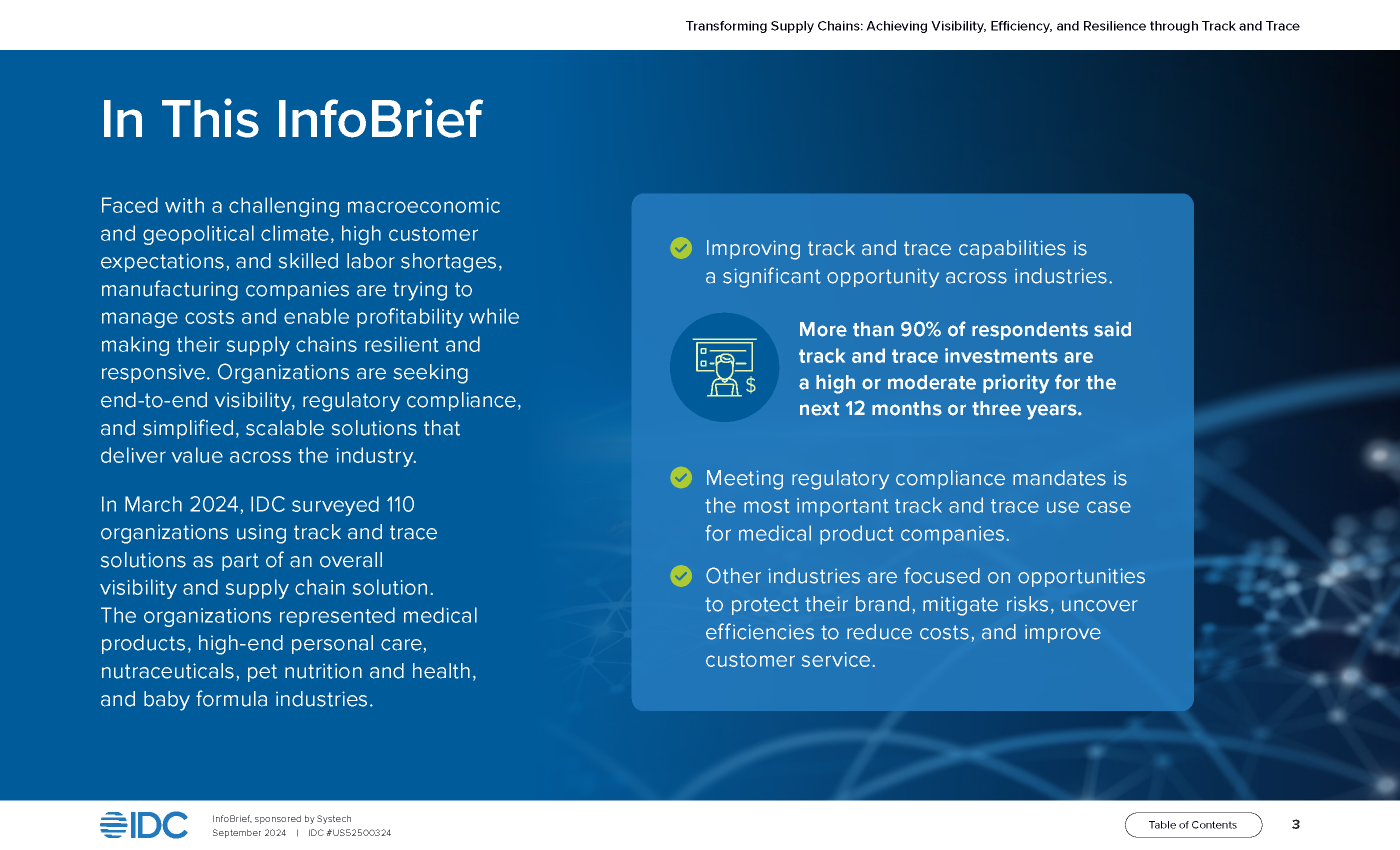

In today’s challenging macroeconomic and geopolitical climate, manufacturing companies are seeking new ways to effectively manage costs and enable profitability while making their supply chains resilient and responsive.

Achieving visibility, efficiency and resilience through track and trace is key to supply chain transformation.

In this InfoBrief, you will:

Learn how track and trace maturity helps organizations increase visibility with supply chain partners

Understand why large, dispersed global supply chains require digital tools to generate a single source of truth

Explore how extensive visibility and agility improve the customer experience to enable profitability

When you look at your own supply chains and evaluate the visibility you have into the movement of your products, is there transparency all the way from sourcing through manufacturing? Supply chain transformation begins with improved track and trace.

IDC surveyed 110 organizations across industries using track and trace solutions as part of an overall visibility and supply chain solution.

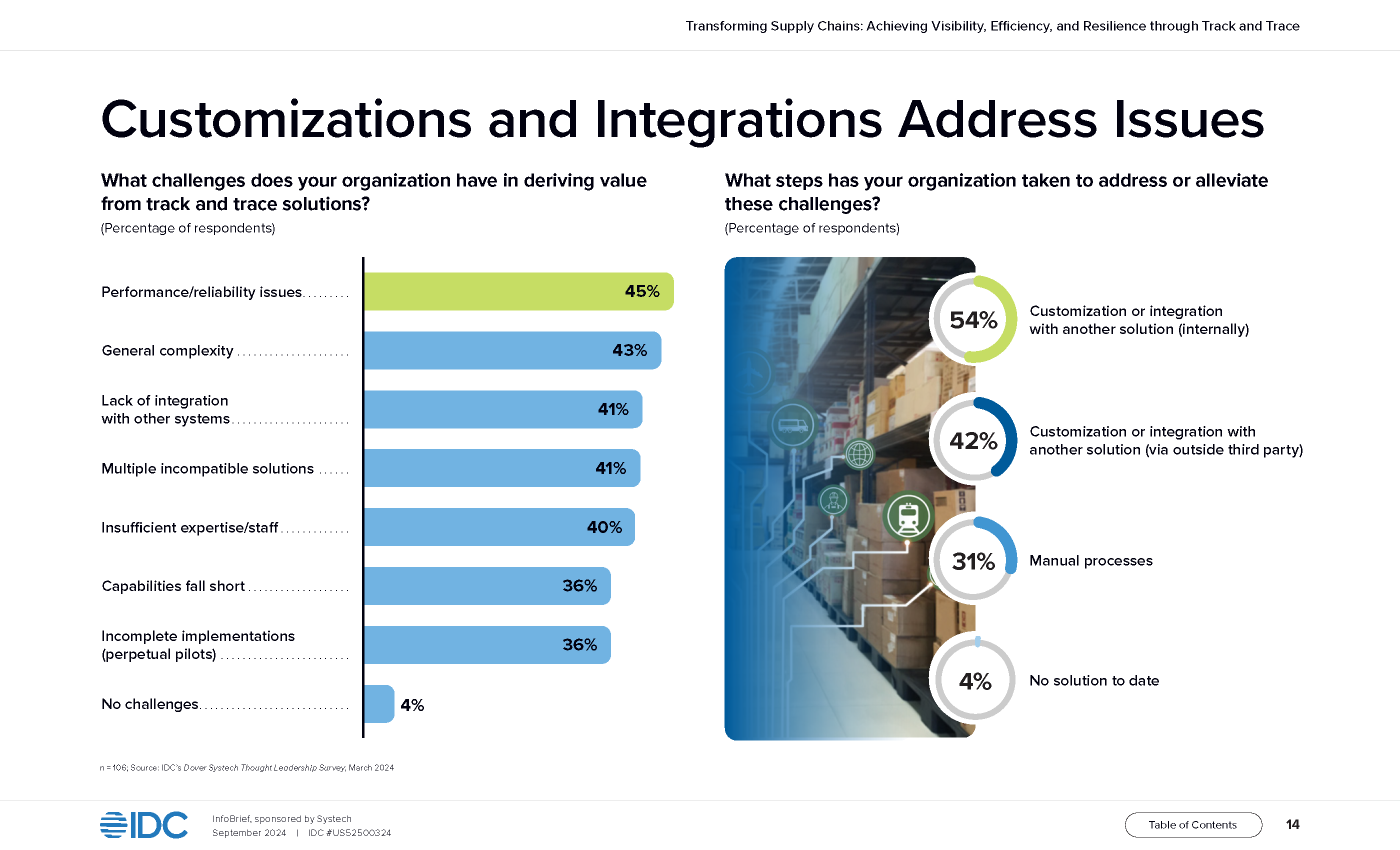

Integration challenges emerge as a driver of inefficacies and ineffectiveness.

Manufacturers’ top priority in their efforts to manage risk better is robust and easily integrated technology that improves visibility.

90% of organizations have deployed track and trace in supply chains. Yet, only 1 in 10 have fully implemented it across their business as an integrated network connecting all partners.

Discover ways to improve track and trace capabilities and take action on what you see.